In this article, I’ll take you through the fascinating journey of how bamboo plants are transformed into eco-friendly clothing.

From harvesting the sustainable bamboo plant to extracting its fibers, cleaning and spinning them into yarn, and finally weaving or knitting them into fabric, the process is both innovative and environmentally conscious.

Join me as we explore the various techniques and methods involved in the eco-friendly processing of bamboo, ensuring that fashion and sustainability can go hand in hand.

Key Takeaways

- Bamboo clothing is a sustainable alternative to traditional cotton farming.

- Bamboo fabric production involves eco-friendly and minimal harm to the environment.

- Bamboo clothing is soft, breathable, and luxurious to wear.

- The production process contributes to a greener fashion industry.

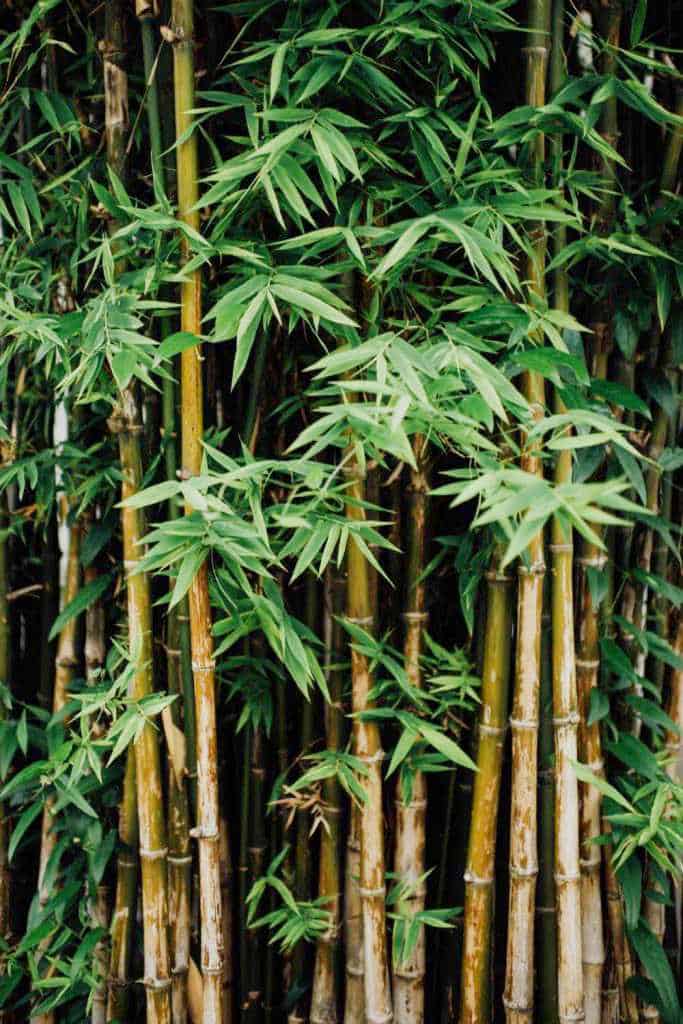

The Bamboo Plant: A Sustainable Resource

The bamboo plant is a sustainable resource that can be used to create eco-friendly clothing. I have always been fascinated by the versatility and resilience of bamboo. Not only does it grow incredibly fast, but it also requires minimal water and no pesticides to flourish. This makes it a perfect alternative to traditional cotton farming, which often involves harmful chemicals and excessive water consumption.

Bamboo fibers are also naturally hypoallergenic and moisture-wicking, which means that clothing made from bamboo can keep you cool and dry in hot weather. Additionally, bamboo fabric is breathable and soft, providing a comfortable and luxurious feel.

Knowing that bamboo clothing is not only stylish but also environmentally friendly, I am excited to support the use of this sustainable resource in the fashion industry.

Harvesting Bamboo: Methods and Techniques

When it comes to harvesting bamboo, it is crucial to ensure sustainable practices that prioritize the long-term health of the plant.

By implementing techniques such as selective harvesting and regrowth management, we can guarantee the continuous growth of bamboo forests.

Additionally, efficient extraction methods can further minimize the environmental impact, making sure that the process is both resource-efficient and eco-friendly.

Sustainable Bamboo Harvesting

To sustainably harvest bamboo for clothing, I can carefully select mature stalks and cut them at ground level. This ensures that the plant will continue to grow and regenerate. When choosing the stalks, I look for ones that are at least three years old, as they are strong and durable.

It’s important to avoid cutting young shoots or using chemicals that can harm the environment. After cutting the stalks, I make sure to remove any leaves or branches, leaving only the clean stalks. This process not only helps in the sustainable growth of bamboo but also ensures that the harvested material is of high quality for making clothing.

Efficient Bamboo Extraction

You can extract bamboo efficiently by selecting mature stalks and cutting them at ground level. This method ensures that the bamboo regrows quickly and remains healthy.

When harvesting bamboo, I make sure to choose stalks that are at least three years old. These mature stalks are stronger and provide better quality fibers for making clothing.

By cutting the bamboo at ground level, I can maximize the yield and minimize waste. After harvesting, I remove the branches and leaves from the stalks, leaving behind a clean and ready-to-use material.

This efficient extraction process not only helps in maintaining a sustainable bamboo supply but also ensures that the fabric produced from it has minimal impact on the environment.

Minimal Environmental Impact

By choosing mature stalks and cutting them at ground level, I can ensure that the extraction process has minimal impact on the environment.

When harvesting bamboo for clothing production, it is important to select stalks that have reached their full maturity. This ensures that the plant has had enough time to establish a strong root system and contribute to the ecosystem.

By cutting the stalks at ground level, I can prevent unnecessary damage to the surrounding plants and soil. This method also allows for the regrowth of new shoots, ensuring the sustainability of the bamboo forest.

Additionally, the extraction process itself is designed to be eco-friendly. Using mechanical methods instead of chemicals, we can minimize the environmental impact and maintain the natural integrity of the bamboo fibers.

Bamboo Fiber Extraction: Turning Plant Into Material

As I dive into the topic of bamboo fiber extraction, I’m excited to explore the world of sustainable bamboo fabric and its many benefits.

In this discussion, I will compare different extraction methods used in turning the bamboo plant into a usable material.

Additionally, I will delve into the environmental advantages that come with using bamboo as a fabric source, shedding light on the positive impact it can have on our planet.

Sustainable Bamboo Fabric

Sustainable bamboo fabric is created through a process that involves breaking down the bamboo plant and extracting its fibers. This eco-friendly fabric is known for its softness, breathability, and antibacterial properties.

As a fashion lover and advocate for sustainable living, I am thrilled by the advancements in bamboo fabric production. The process begins by harvesting mature bamboo stalks, which are then cut into smaller pieces and soaked in a solution to soften the fibers.

Next, the fibers are mechanically extracted and spun into yarn. This yarn is then woven into fabric, which can be used to make a variety of clothing items. The best part is that bamboo fabric is biodegradable and requires less water and pesticides to grow compared to traditional cotton.

It’s a win-win for style and the environment!

Extraction Methods Comparison

In my previous discussion, I explored the concept of sustainable bamboo fabric. Now, let’s delve into the various extraction methods used to transform bamboo into fabric.

There are two primary methods: mechanical and chemical. The mechanical method involves crushing and then decorticating the bamboo to obtain the fibers. This process is eco-friendly, as it requires minimal energy and chemicals.

On the other hand, the chemical method involves using harsh chemicals, like sodium hydroxide, to break down the bamboo and extract the fibers. Although this method yields softer and finer fibers, it has a more significant environmental impact due to the chemicals used and the energy required.

Considering the eco-friendly nature of bamboo clothing, it is essential to choose fabrics made using the mechanical method. This way, we can ensure that our clothing is not only sustainable but also minimally harmful to the environment.

Environmental Benefits of Bamboo

When you choose bamboo as a material, you are making a positive impact on the environment. Bamboo has numerous environmental benefits that make it an eco-friendly choice.

Firstly, bamboo grows quickly, making it a renewable resource. It can be harvested in just a few years compared to hardwood trees that take decades to mature.

Additionally, bamboo requires minimal water and no pesticides or fertilizers to grow, reducing the strain on water resources and limiting soil contamination.

Moreover, bamboo is a natural carbon sink, absorbing more carbon dioxide and releasing more oxygen than other plants. This helps to combat climate change and improve air quality.

Bamboo Fiber Processing: Cleaning and Preparing for Spinning

After the bamboo stalks are harvested, they are thoroughly cleaned and prepared for spinning into fiber. I start by removing any leaves or branches from the stalks. Then, I use a machine to strip off the outer layer, called the epidermis. This process helps to remove any impurities and ensures that we are left with just the inner fibers of the bamboo.

Once the stalks are stripped, they are washed in water to remove any remaining dirt or debris. After the washing process, the bamboo stalks are left to dry naturally in the sun. Once they are fully dry, they are ready to be spun into fiber.

This cleaning and preparation process is crucial in ensuring that the bamboo fiber is of high quality and ready to be made into eco-friendly clothing.

Spinning Bamboo Fiber: Creating Yarn for Fabric

To create yarn from the prepared bamboo fibers, you’ll need to feed them into a spinning machine. It’s quite a fascinating process!

As I carefully place the fibers into the machine, I can’t help but marvel at the transformation taking place. The machine begins to spin the fibers at a high speed, twisting them together to form a strong and durable yarn. It’s incredible how something as simple as bamboo can be turned into a textile material.

Once the yarn is created, it can be used to make various bamboo clothing items, from shirts to socks. I feel a sense of pride knowing that I am contributing to the production of eco-friendly and sustainable fabrics.

Bamboo Fabric Production: Weaving and Knitting Techniques

As I weave the bamboo yarn together, the intricate patterns and textures begin to emerge, creating a beautiful and unique fabric.

The weaving process is an essential step in creating bamboo fabric, as it brings the yarns together to form a cohesive material. It requires skill and precision to ensure that the threads are aligned perfectly, resulting in a strong and durable fabric.

I carefully manipulate the loom, interlacing the horizontal and vertical yarns to create different patterns and designs. The versatility of bamboo yarn allows me to experiment with various weaving techniques, such as plain weave, twill weave, or satin weave, each producing a distinct texture and appearance.

It is truly fascinating to witness the transformation of simple bamboo yarn into a stunning fabric that is not only eco-friendly but also soft, breathable, and luxurious to wear.

Eco-Friendly Finishing: Dyeing and Printing Techniques

By using natural dyes and innovative printing techniques, I can ensure that the finishing process of bamboo fabric is environmentally sustainable and free from harmful chemicals.

Natural dyes, derived from plants and minerals, are a safe and eco-friendly alternative to synthetic dyes. These natural dyes not only produce vibrant and long-lasting colors, but also have minimal impact on the environment during the dyeing process.

Additionally, innovative printing techniques, such as digital printing, allow for precise and efficient application of designs onto the fabric without the need for excessive water or chemicals. This reduces waste and further minimizes the negative environmental impact.

Frequently Asked Questions

How Long Does It Take for Bamboo to Grow and Be Ready for Harvesting?

It takes bamboo approximately 3 to 5 years to grow and be ready for harvesting.

Are There Any Specific Environmental Benefits to Using Bamboo as a Clothing Material?

There are specific environmental benefits to using bamboo as a clothing material. It is renewable, requires less water and pesticides, and produces more oxygen than other plants.

Can Bamboo Fabric Be Used for All Types of Clothing or Are There Limitations?

There are some limitations to using bamboo fabric for all types of clothing. For example, it may not be suitable for heavy-duty or high-performance garments due to its softness and less durability.

What Are the Advantages of Using Bamboo Fabric Compared to Other Eco-Friendly Materials?

Compared to other eco-friendly materials, bamboo fabric has numerous advantages. It is not only soft and breathable, but also hypoallergenic, antimicrobial, and thermoregulating. It’s a sustainable choice that offers comfort and health benefits.

Are There Any Specific Care Instructions for Bamboo Clothing That Consumers Should Be Aware Of?

Yes, there are specific care instructions for bamboo clothing. It is important for consumers to be aware of these guidelines in order to properly maintain the fabric’s quality and prolong its lifespan.

Conclusion

In conclusion, I’m truly amazed by the eco-friendly processing of bamboo clothing, from plant to fabric.

It is remarkable how bamboo, a sustainable resource, can be harvested and transformed into a soft and durable fabric.

The extraction and processing techniques ensure that the fabric is clean and ready for spinning, which then leads to the creation of yarn for weaving or knitting.

The finishing techniques, such as dyeing and printing, are also done in an eco-friendly manner.

Overall, bamboo clothing is a fantastic example of sustainable fashion.